So, you want to make a beautiful business card to make an impression? Great!

There is nothing worse than a cheap, tacky card. They are unsustainable as they are more than likely thrown in the bin not long after your new contact gets home.

Having a quality, specialised business card shows your potential customer a lot about you and your business. It shows your attention to detail, that you respect your business and gives a sense of trust you will provide a better service than ‘the next guy’... They are also more likely to be kept, or even better, passed on to an associate after they have dealt with you.

Embossing VS Debossing | embossing and debossing difference | letterpress vs deboss | know your print finishing

Print finishing comes in many forms: Embossing, Debossing, Letterpress, Foil Stamping, Raised UV, 3D UV, Spot UV Die Cutting and more!

The Difference:

Discussing Embossing and Debossing is a common conversation we have with clients. Both terms are often confused and choosing the wrong finishing will result in very different outcome.

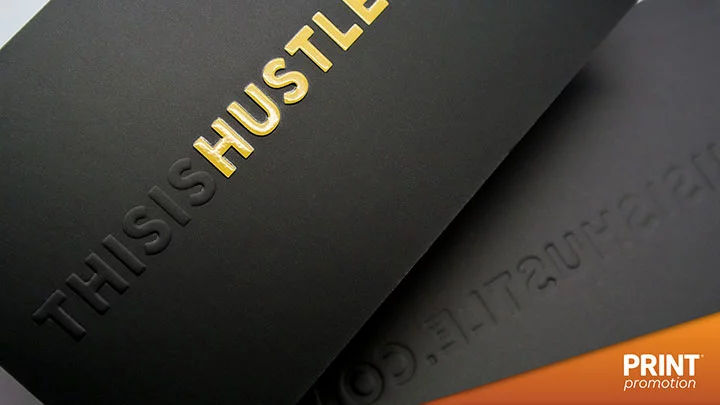

Embossing

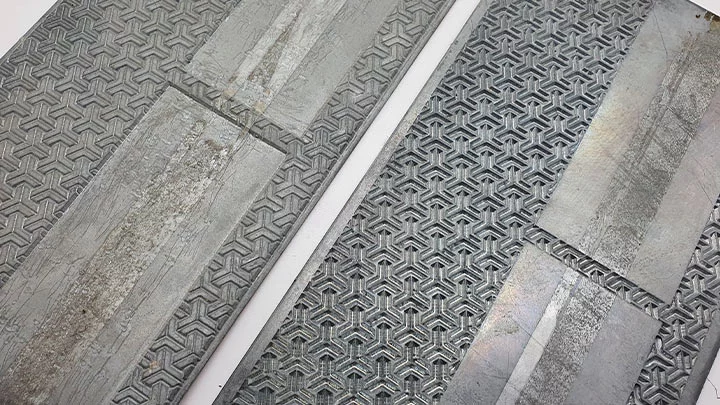

Embossing is made by two metal plates. The plates are placed on either side of the card and pressed together. Artwork from the back is pushed into the card (leaving an indentation) and extrudes through to the front of the card.

Debossing

is made by a single metal plate. The plate is placed on the side of the artwork and pressed in leaving an indentation. The back of the card is not affected (in some cases a slight ‘pressure mark’ may be visible under certain light). Note debossing can only be done on certain thicker stocks and is subject to artwork approval. In some instances, large coverage with debossing does not work well as more pressure is required which can result in the back of the card having heavier pressure marks.

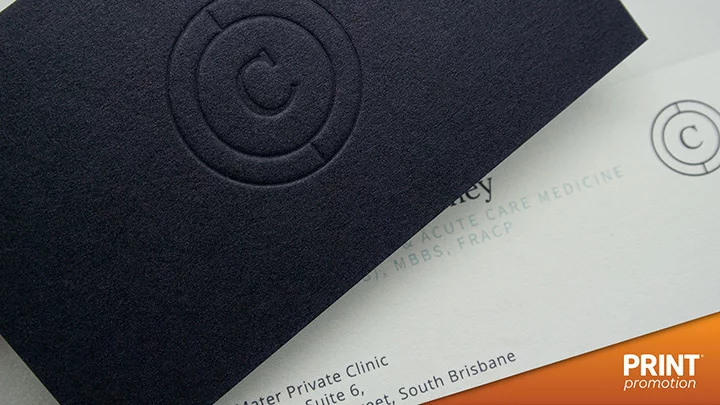

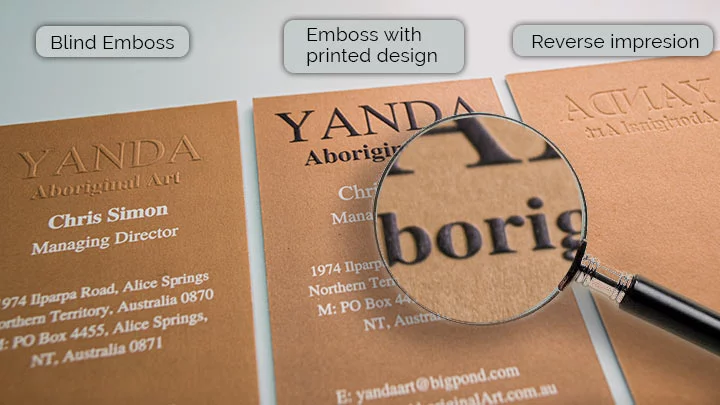

Blind Embossing and debossing

This is essentially not using a different print colour in the area that will be embossed / debossed. Generally, we recommend this as contrast can hide the embellishing effect. Creating a card that is ‘not blind’ means the card is printed, then the embossing or debossing is applied. In some cases there can be slight misalignment between the processes.

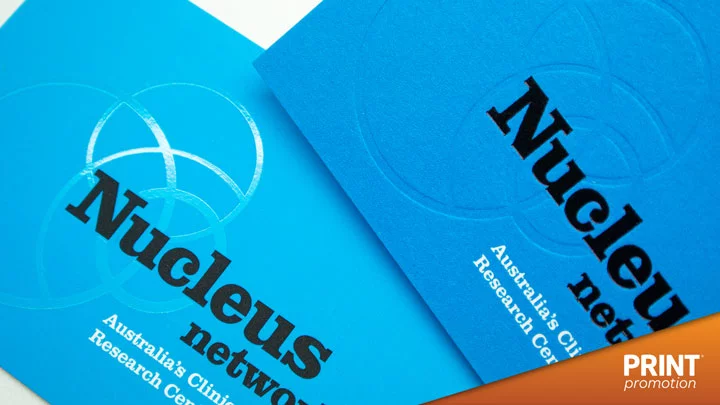

Debossing VS Spot UV

This image shows the same design on two completely different cards.

Debossing VS Foil

This image shows the same design on with different finishing.

Letterpress

is an old-fashioned process of debossing with ink on the plate. Essentially the card is printed and debossed at the same time. This is a more expensive process which is more limited in its application. Letterpress is more commonly used in simplistic designs - eg text based wedding invitations.

Some designs really benefit from adding additional finishing processes, other designs are best left at one. It really comes down to the individual design.

Embossing + Spot UV

is a clear transparent gloss that is placed over the matt laminate. The result is beautify contrast of gloss artwork against the matt background. If done right, light reflects off the shiny components to draw attention. Some designs benefit by adding SPOT UV on top of the embossing.

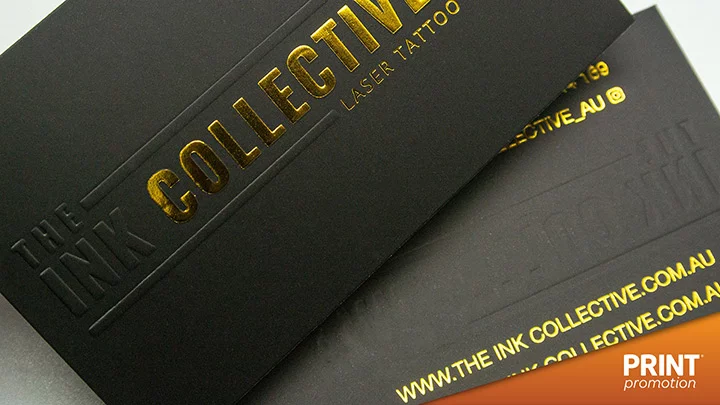

Embossing + Foil Stamping

Some designs benefit by using Foil stamping on top of the embossing. Foil Stamping is not print, it is added after the card is printed. Essentially, it is a thin metallic foil (think something like aluminium foil) that is pressed on to the card. It has a metallic – high reflective chrome look and is available in many colours.

So what if you want artwork ‘sticking out’ without an impression on the back?

Standard embossing requires a two-sided block. one side sticks out, the other side is pressed in. As mentioned above, this is embossing. When designing a business card,

the reverse impression of the emboss limits design. So can you have embossed business cards without having an indent in the back?

Simple answer is YES! This can be achieved by two methods:

Scodix (Raised UV):

3D UV is a high gloss transparent film that sits on top of the velvet laminate. Similar to SPOT UV, the fundamental difference of 3D UV is the height. Spot UV sits flat on top of matt laminate. 3D UV has the height of 0.05 mm and is noticeable to the touch.

Laminated business cards

Laminating is a process of adding a thin transparent plastic to the card after it has been printed.

This process is also known as Cello glazing. Laminate is added to cards for both aesthetic and protective purposes.

Lamination is commonly done on a more budget stock that is not fibrous – such as 350 or 450 gsm artboard.

There is no point laminating a textured or fibrous stock as you cannot see / feel the stock – only the laminate. Laminate is offered in the following.

LAMINATED card range

-

Gloss: a high shine gloss. This was more popular in the 90s.

See gloss business cards examples.

Finishing options: Please note we only offer die cutting on gloss laminated cards as foil stamping does not stick as well, and UV is basically seen.

Embossing blemishes the gloss – so that’s out too.

-

Matt: a matt finish. This is more contemporary.

-

Matt Velvet: This looks the same as matt but feels like velvet / swede to the touch. A more premium product.

Finishing on matt or matt velvet includes: Foil stamping, Embossing, 3D UV and Spot UV. Debossing is not available as the process causes blemishes.

See Matt laminate business cards examples.

Uncoated business cards.

Uncoated basically means the stock is matt / raw stock and does not have additional varnishes added. At Print Promotion, we categorise all of our unlaminated cards in this class.

From budget to high end, we have a leading range of quality stocks to suit most budgets.

Print promotion has been specialising in business cards since 2004.

We have helped thousands of businesses reach their potential, not just by the printing, but by our consultation process that provides options for consideration.

UNCOATED card range

Card Range

Here is the full range of card product we offer embossing, debossing, letterpress and raised UV.

| Stock | Thickness |

|---|---|

| 270 gsm Regan | 0.35mm ≅ |

| 350 gsm ( Matt laminated) | 0.45mm ≅ |

| 330 - 400 gsm Textured | 0.35mm > 0.45mm ≅ |

| 350 gsm Premium | 0.35mm ≅ |

| 360 gsm Numil | 0.6mm ≅ |

| 450 gsm ( Matt Velvet laminated) | 89 x 54mm |

| 450 gsm Craft board | 0.7mm ≅ |

| 550 gsm Premium Cotton | 0.72mm ≅ |

| 680 gsm Pitch Black | 0.8mm ≅ |

| 700gsm gsm Duplex | 0.92mm ≅ |

emboss | debossed | embossed | deboss | embossing vs letterpress | cards | print | printing | design | packaging

debossed, embossed, deboss, embossing vs letterpress, embossed and debossed, emboss vs deboss, embossing and debossing, debossing and embossing, deboss or letterpress carbon balanced print, balanced print custom, metal business cards, print custom printed, printing display print, print services litho, wooden business cards, black metal cards, business cards premium, metal cards luxury, printing, design, boxes, packaging

Servicing Australia and beyond.

Brisbane printing or design, New Farm printing or design, Teneriffe printing or design, Chandler printing or design,

Ascot printing or design, Burbank printing or design. Hamilton printing or design, Bulimba, Brookfield, St Lucia, Chelmer,

Surfers Paradise embossing and debossing.

Paradise Point printing or design, King Seaforth printing or design, Malvern printing or design, Middle Cove embossing and debossing, Castlecrag. Claremont, Swanbourne, Castle Cove, Roseville, Mosman Park.

Balmain debossed, Milsons Point embossed, Kirribilli, Double Bay, Albert Park, Brighton, Berrimah, City Beach. Broadway, Nedlands, Crawley, Dalkeith.

Woollahra, Hunters Hill, Woolwich, Mosman, Portsea, Dover Heights, Vaucluse, Hawksburn, Toorak. Cottesloe, Peppermint Grove.

Bellevue Hill, St Andrews, Darling Point, Edgecliff. Northbridge, Ringwood, Eltham. Hawthorne, Greensborough, Camberwell, South Yarra, Byron Bay, Brunswick.

Print Promotion. We have been specialists in print finishing since 2009 and are happy to provide free consultation how to get the most

out your project. NO two jobs are the same, as no business is the same. As such each job should be treated with due process.

We offer first rate consultation to offer the right stock and the right finishing for your next upcoming job. The process is usually pretty quick once timeframe and budget is ascertained.

Further to this, we created this page to provide additional information regarding prepress – to ensure your artwork will turn out as intended. In addition, a comprehensive run down on all things print finishing – examples of how you can expect the product to turn out.

Who are we?

Print Promotion is a division of Arcane Media based in Brisbane, Queensland. We are a premium design and printing consultancy that specialises in creating or enhancing your visual corporate image. Our skilled team of seasoned graphic designers have the experience and marketing insight to ensure your image will effectively relate to your target demographic. We have an Australia-wide client base, servicing: hospitality and tourism; professional services; construction and trade; media; mining; recruitment; automotive; defence and the health business sectors.

Contact us today to discuss your next design or print project.

Call 1300 669 211

We design. We print. We deliver.

Chandler | Ascot | Burbank | Hamilton | Bulimba | Brookfield | St Lucia | Chelmer | Surfers Paradise | Paradise Point King | Seaforth | Malvern | Middle Cove | Castlecrag | Claremont | Swanbourne | Castle Cove | Roseville | Mosman Park | Balmain | Milsons Point | Kirribilli | Double Bay | Albert Park | Brighton | Berrimah | City Beach | Broadway Nedlands | Crawley | Dalkeith | Woollahra | Hunters Hill | Woolwich | Mosman | Dover Heights | Vaucluse | Hawksburn | Cottesloe | Peppermint Grove | Bellevue Hill | St Andrews | Darling Point | Edgecliff | Northbridge | Rindwood | Eltham | Greensborough | Camberwell | South Yarra | Byron Bay | Brunswick